In healthcare facilities, ventilation goes way beyond whether you're just hot or cold. A healthcare ventilation system reduces hospital infections and maintains indoor air quality while following specific industry standards.

For example, ventilation rates are defined in the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) Standard 62.1 and Standard 170. The design and installation of utilities to meet patient care and operational needs are critical. Implementing strategies to manage the ventilation and HVAC systems keeps patients, visitors, and employees safe.

In the past three years, CHT has managed to navigate the ebbs and flows of the pandemic with our typical balanced approach to ventilation control. CHT provides pressure and airflow tests with documentation as part of your Vitaleyez™ program profile that satisfies the codes. As healthcare facility managers, you must ensure compliance, become a more impactful facility leader, and leverage real-time data to make informed decisions.

This article discusses hospital ventilation airflow with planned steps to increase your HVAC system compliance and develop a ventilation management program (VMP) for your healthcare facility.

What is HVAC System Compliance in Hospitals?

The goal of the HVAC design is to efficiently and effectively provide a safe and comforting environment.

Healthcare HVAC system design requires specific codes, guidelines, and standards to meet compliance. As a result, they need high-quality construction more than other types of installations.

Medical facilities can demand varying temperature levels depending on the environment. For example, ORs have been typically kept colder for the staff and the specialized medical equipment. Surgical suites and imaging spaces are ventilated following Standard 170, also referenced by FGI (Facilities Guidelines Institute).

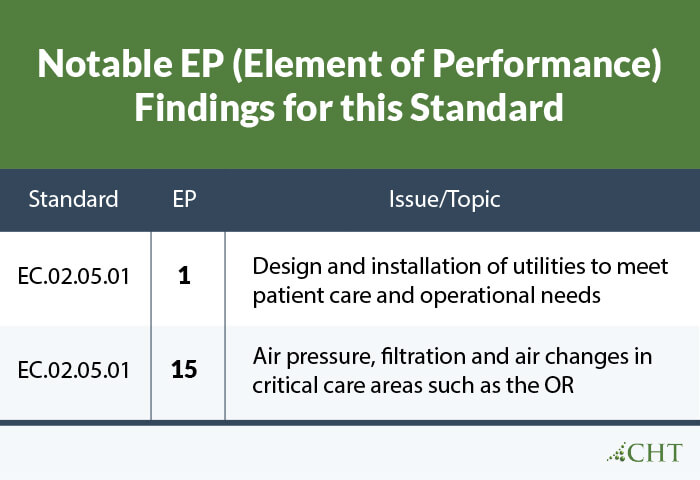

Along with the FGI and ASHRAE, the Joint Commission looks to improve standards and safeguard patients. The EC.02.05.01 Standard (The hospital manages risks associated with its utility systems) is just one of the standards to help healthcare organizations improve their performance.

Managing Risk Associated with Utility Systems

A life safety surveyor will note the deficiency if a marked room is not compliant with TJC's standard (EC.02.05.01). For example, a non-compliant issue could be related to air pressure, filtration, and air changes in critical areas such as the OR.

Resource:

The Joint Commission - Physical Environment Portal: Module 1, EC.02.05.01 Leadership

The Process to Develop a Ventilation Management Plan

The American Society for Healthcare Engineering (ASHE) says,

The Ventilation Management Plan (VMP) aims to create a comprehensive strategy to test and maintain all areas identified that require any ventilation management, including pressure, temperature, humidity, air changes, or filter requirements. VMP floor plans can complement the VMP and provide mapping showing the pressure risk ranking of spaces and airflow direction from the spaces.

ASHE, Health Facilities Management, suggests a 9-step process to develop a ventilation management program (VMP) for healthcare facilities, from forming a committee to regular maintenance.

- Form a committee - Get buy-in from your leaders in the organization.

- Determine the code reference - As mentioned above, there are numerous codes and standards that include ventilation requirements.

- Develop a source of truth - The committee will need to develop a comprehensive list of all the spaces in the facility with ventilation requirements. (Determine naming conventions ahead of time.)

- Risk ranking - risk assessment procedures will drive all building system categories. Ranking risk spaces will go according to ventilation needs. NFPA 99 outlines the four categories of risk.

Category 1 - The system must always be highly functional. Failure may cause death or serious injury. An example in this category would be a medical gas system in an ICU.

*An example of the VMC approach in this category would be the pressure, temperature, and humidity within an operating room.

Category 2 - A system failure would not involve risk to life. High dependability is expected in this category. Failure is limited to minor injuries.

Category 3 - Failure would cause discomfort but is not likely to cause injury.

Category 4 - Patients are not adversely affected – No impact on patients or caregivers.

- Excursion response plan - "Given the number of spaces within a hospital, it is inevitable that room pressure, temperature, or humidity will fall out of range at some point. Risk rankings should be used to prioritize the response times when excursions occur." [source]

Considering category rankings, the temperature, humidity, and pressure in an operating room would likely cause an OR to rank in Category 1. Any excursion of the three could be regarded as life-threatening during surgery. - Educate the committee - All leaders should have education on any ventilation-related definitions and information. They should familiarize themselves with the basic elements of pressurization, different temperatures throughout the hospital, air quality, and air changes.

- Create a policy - A policy and document for the entire hospital should be handy and easily referenced.

- Approval - Appropriate approval from the organized team will keep the plan actionable and moving forward.

- Maintain the program - Plan for regular maintenance and updates.

Conclusion

We understand the need to achieve HVAC system compliance. We also understand you want your medical gas systems to be compliant, pass inspection, and above all, increase patient safety. It’s crucial to keep your medical gas systems running smoothly so you have no unexpected failures and have the proper equipment to do your job competently and worry-free.

CHT's certified technicians conduct medical gas inspections and testing to help you meet NFPA 99 regulations and pass the Joint Commission and CMS. We provide pressure and airflow tests with documentation as part of your Vitaleyez™ program profile that satisfies the codes.

Vitaleyez™ has everything you need to make informed compliance decisions all in one place, allowing you to get problems resolved in less time and with less effort.

Request a demo today!