Inspection, Testing & Maintenance

Inspection, Testing & Maintenance

Get Verified Results for your Medical Gas system.

VacWash

VacWash

Clean your medical vacuum system to provide optimal pressure.

Environmental Monitoring

Environmental Monitoring

Maintain the health of your employees in your facility.

Installation

Installation

Ensure patient safety, reduce risk, and increase your profitability.

Training

Training

ASSE medical gas certification training for your people.

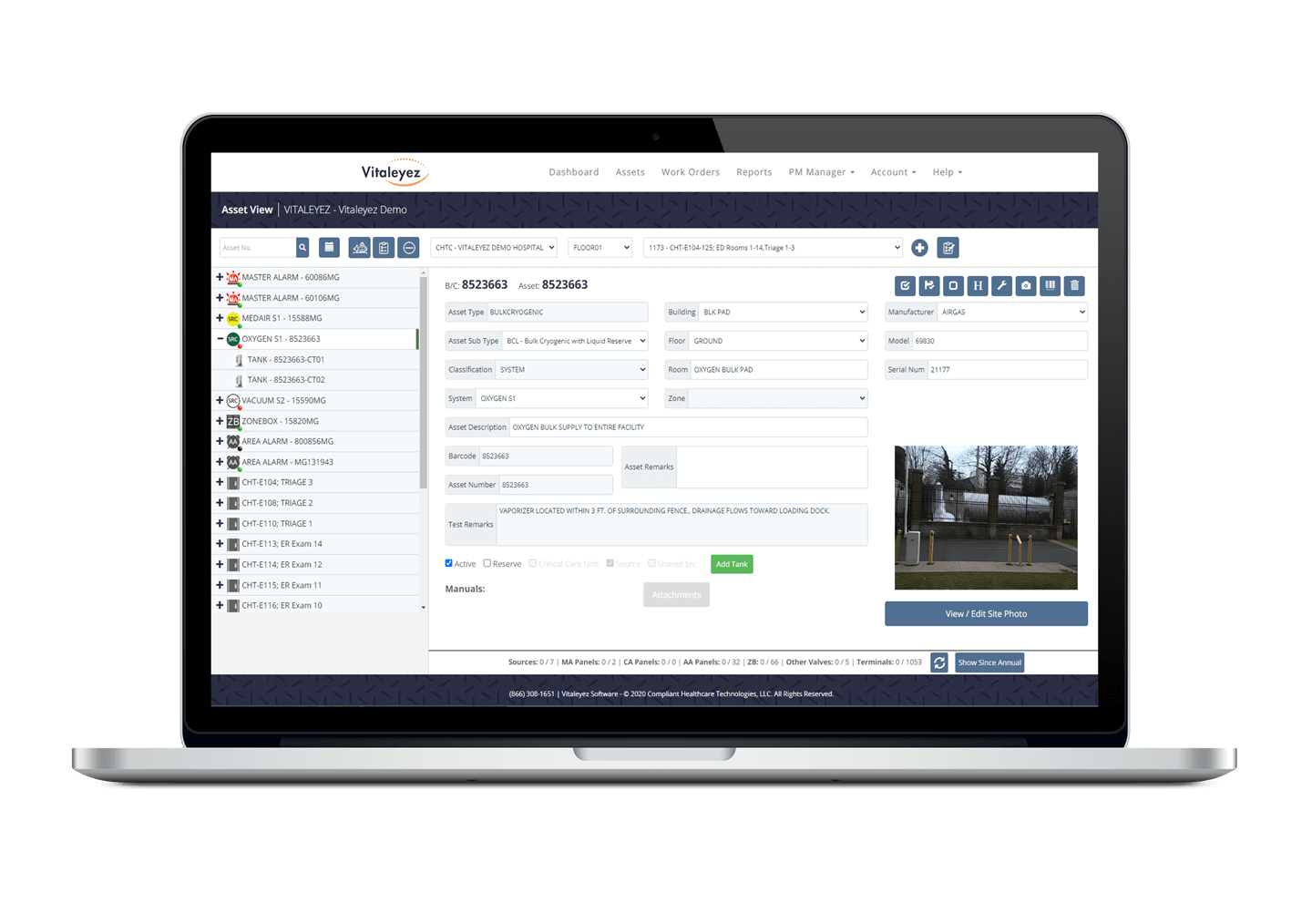

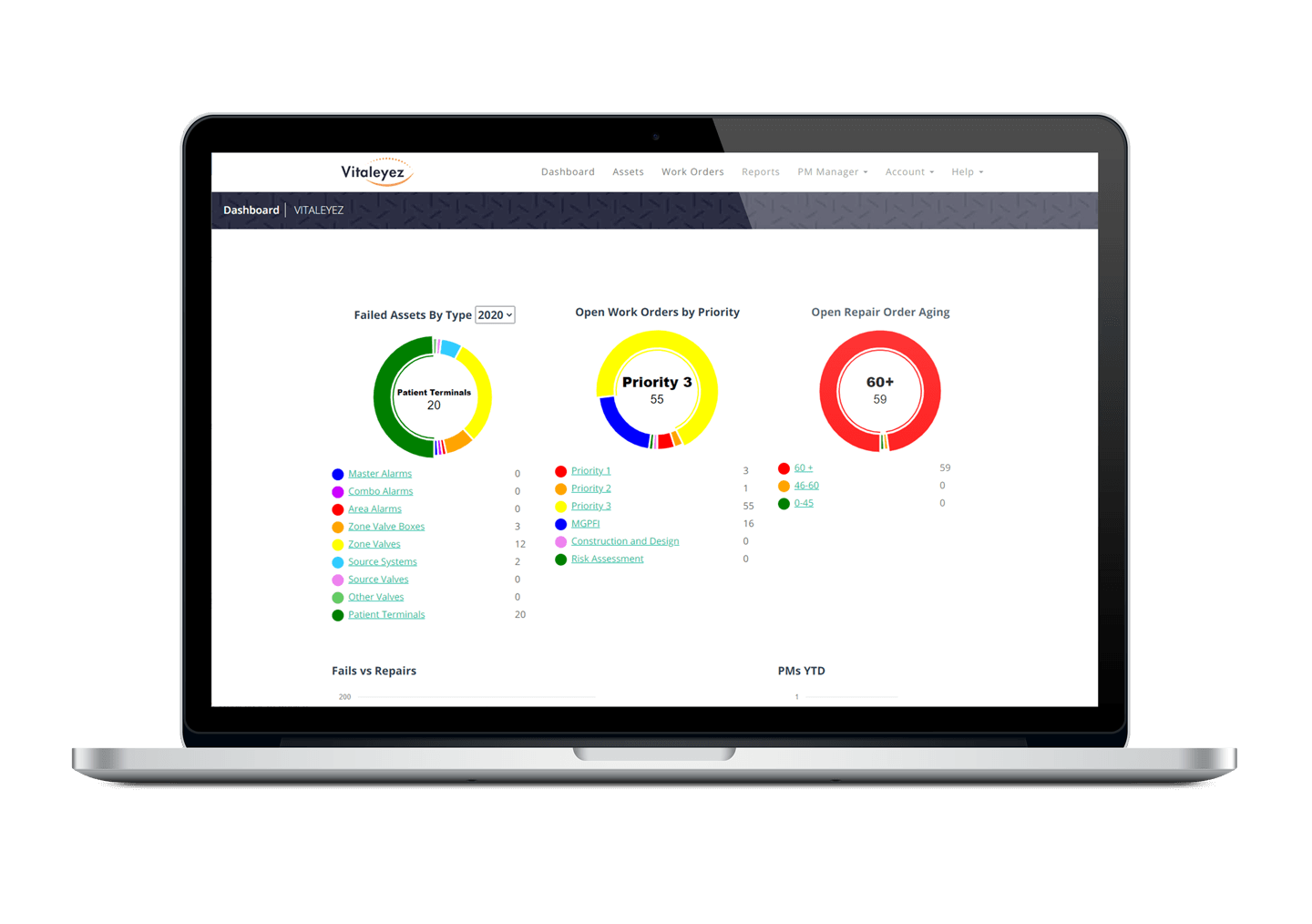

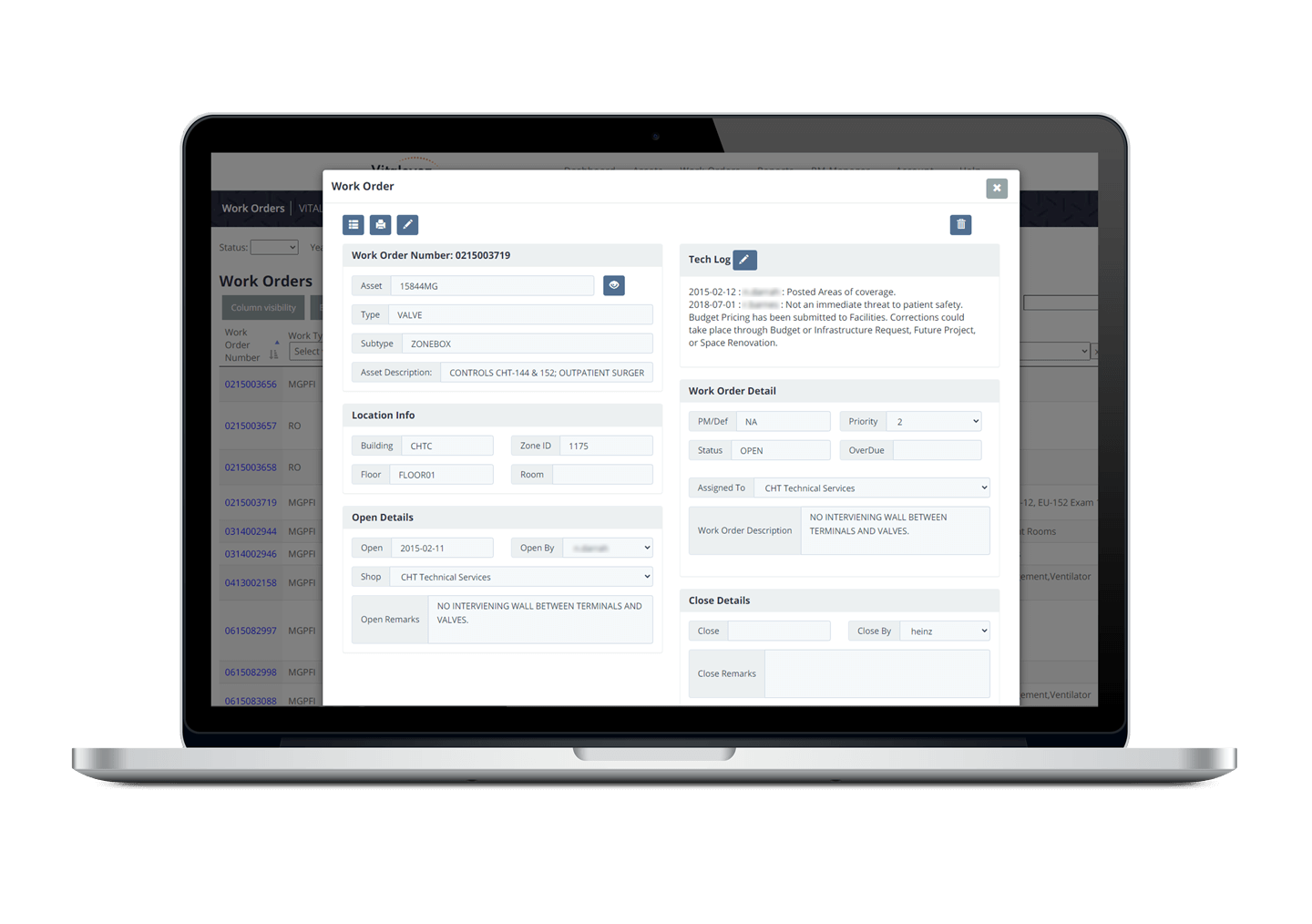

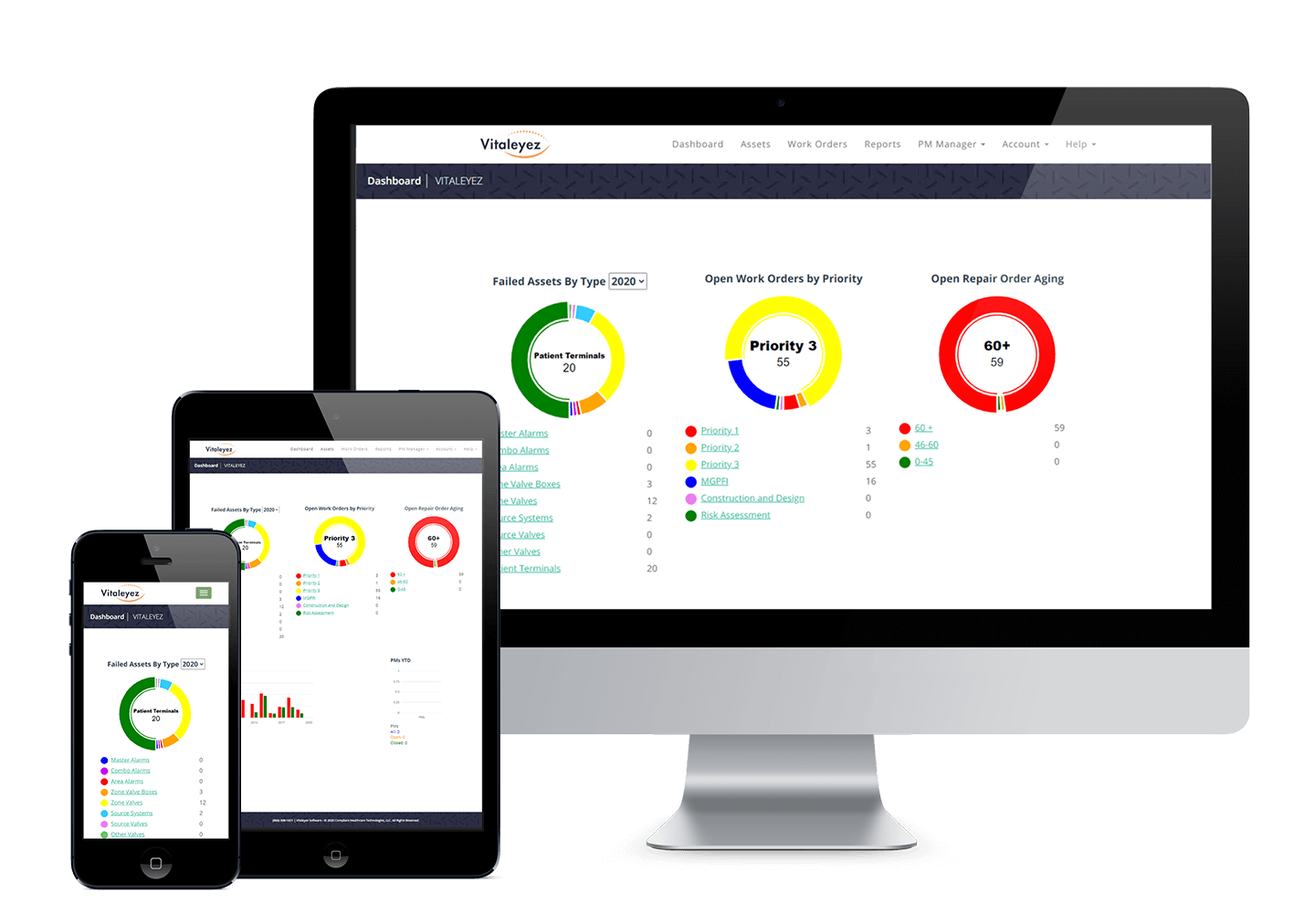

Inspection, Testing & Maintenance

Inspection, Testing & Maintenance

Get Verified Results for your Medical Gas system.

VacWash

VacWash

Clean your medical vacuum system to provide optimal pressure.

Environmental Monitoring

Environmental Monitoring

Maintain the health of your employees in your facility.

Installation

Installation

Ensure patient safety, reduce risk, and increase your profitability.