The National Fire Protection Association, or NFPA, has set a standard for health care compliance rules and regulations. Any time a facility is considering installing gas for use in an establishment, there are codes facility managers must follow and safety measures to be taken in order to provide a safe environment.

NFPA 99 establishes all of the criteria to be met for various levels of medical establishments in order to provide a safe environment for the medical teams, patients, and any structure or persons in the surrounding area. Using medical gas in the wrong fashion can create serious consequences, even the possibility of fires and explosions.

Are you struggling with Medical Gas Compliance?

CHT offers medical gas services to help you reach your compliance goals. To help you navigate through these challenges, start with a free 30-minute discovery call.

Here's a quick look at what the requirements NFPA 99 pertains to:

- Maintenance

- Performance

- Installation

- Testing

- Safety Practices

- Inspection

These are the categories of requirements that facility materials, equipment, and appliances including medical gas and vacuum systems are subject to.

Medical Gas Requirements

NFPA 99 provides criteria that follow a risk-based approach, where it is the risk posed to patients and staff, not the type of building, that defines safety guidelines. When having gas installed for use at medical facilities, a risk assessment should always be performed. When a risk assessment is done you should look for any potential risk of injury, death, or fatality that may occur if there is a system failure or malfunction.

The four risk categories are:

- Category 1 - Failure of the system or equipment is likely to cause major injury or death to patients or caregivers

- Category 2 - Failure of the system or equipment is likely to cause minor injury to patients or caregivers

- Category 3 - Failure of the system or equipment is not likely to cause injury, but rather patient discomfort

- Category 4 - Failure of the system or equipment would have no impact on patient care

Medical Gas Storage

With the exception of medical air compressors, no motor-driven equipment is allowed in the same space used for medical gas storage. In existing facilities it is common to see motor-driven equipment in the same room as medical gas storage. However, this requirement does not apply to existing facilities, it is only for new facilities.

Another requirement to keep in mind is that for bulk outdoor storage you need to have a minimum of two exit routes.

Medical Gas Systems

Unlike the no motor-driven equipment requirement in the medical gas storage room, labeling requirements are retroactive. This includes labeling of piping, alarms, and valves. Unfortunately, inaccurate valve labeling is a very common problem in health care facilities. Meaning you should review yours now if you haven't already.

The problem with labeling tends to be more with zone valves and area alarms. In fact, 50% of hospitals surveyed have errors with the labeling of zone valves. A common issue is having the labeling associated with the architectural room numbers, rather than correctly using the actual room numbers. This problem even exists in the installation of brand new systems. The purpose of this requirement is such that your staff can determine what valve needs to be closed when there is a fire in the room, and be able to do it quickly.

NFPA Requirements

It is imperative that you have your equipment and systems checked regularly. You should also have your systems and equipment operational maintenance records, as well as repair information on hand. Medical gas compliance is very important since it not only keeps patients and staff safe, but also keeps your information up to date.

You always want to keep all of your equipment and systems up to code. The best way to do this is to check the NFPA regularly for updates. You can find any of the current codes and regulations in the NFPA 2018 handbook.

Let's take a quick look at 5 regulations in particular...

- Annual reviews of all of your bulk oxygen system capacity are required to ensure systems are sized properly.

- All of the central supply systems must be fully inspected yearly, including all of the major components.

- Periodic inspections of the warning systems and alarms is necessary.

- Inspection and calibration of the carbon monoxide monitors on the air systems in the facility is required annually, but it is suggested by the manufacturers to have it inspected and maintained quarterly.

- Maintenance programs for all of the central supply systems and equipment must be met according to the manufacturers recommendations and they should be inspected and maintained quarterly.

Important Updates to the Current 2018 Edition

The NFPA 99 2018 edition has some important updates that broaden the Code’s scope and help you and your facility operate more efficiently.

- Chapter 4 - risk assessment requirements have been revised to clarify the responsibility for conducting a risk assessment and determining risk categories.

- Chapter 5 - the use of oxygen concentrators as central supply sources for piped medical gas systems is allowed.

- Corrugated medical tubing is a permitted material for medical gas and vacuum systems.

- Chapter 7 - requirements for wireless phone & clinical information systems integration.

- Chapter 14 - compiles the requirements for inspection, testing, and maintenance for facilities into one section.

- Chapter 15 - a new chapter dedicated to the application of piped gas and vacuum systems.

These are just some of the updates made to the NFPA 99 2018 edition. Please be sure to review the current regulations to maintain your safety and compliance.

Conclusion

For more information on codes, inspections, and safety measures feel free to check out the NFPA 99 yourself. You should note that your local area conditions may apply differently according to states regulations and policies. It is always important to have, and know, all of the facts before having medical gas installed in a facility for the safety of the medical staff, patients, visitors, as well anyone outside of the area.

CHT offers medical gas services to help you reach your compliance goals. To help you navigate through these challenges, we offer a free 30-minute discovery call.

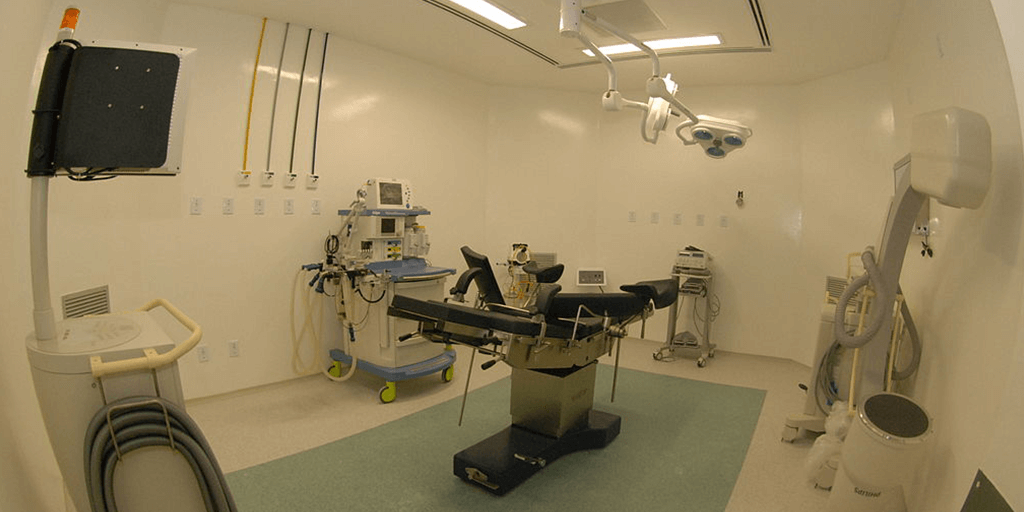

Photo Credit: Operating Theater